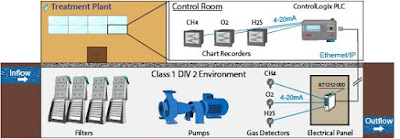

Defining the Problem:

In a wastewater treatment plant, remotely mounted gas detectors monitoring Methane CH4 (ceiling), Oxygen O2 (6 ft high) and Hydrogen Sulphide H2S (floor) have analogue outputs. The gas levels need to be saved to chart recorders located in a control room a long distance away in the plant. To save on the cost of running copper twisted pair wires, we would like to network the analogue outputs for transmission over the Ethernet infrastructure.

System Requirements:

A ControlLogix PLC in the control room can communicate using Ethernet/IP protocol. The Ethernet remote I/O will accept 4 – 20mA inputs from the gas detectors and convert to Ethernet/IP. The PLC will output 4 – 20mA to the chart recorders nearby. Also, the hazardous area requires Class 1 Div 2 instruments.

| Implementing the Solution: | Featured Products: |

| 1. In the USB configured XT software, set the IP address, network parameters and input scaling. | • XT1212-000 |

| 2. Configure the PLC with Acromag’s ControlLogix application note. This document includes instructions for RSLogix 5000 and RSLinx. | |

3. With the XT1212-000 software and inputs wired, poll the module and check the measurements using the test page.

4. Validate the Ethernet/IP communications with an Ethernet connection between the XT and the PLC.

Why Acromag:

The XT series of Remote I/O has Class 1 Div 2 ratings for hazardous locations where the Gas Detectors are installed. With simple software configuration and an application note detailing the PLC configuration, installation and testing are easily accomplished.

This application note was produced by our supplier Acromag.

To find our more information on the products used in this application in Australia, please contact Metromatics on 07 3868 4255 or sales@metromatics.com.au

For outside this area, please contact Acromag on +1 877-295-7035

|

No comments:

Post a Comment